This is a photo log of the build of my 1/12th scale (26.5″) Sopwith Triplane. I’m still building, and will update this post with new photos as I take them.

- Emax GF2215/20 60 gram Outrunner Brushless Motor

- Emax Budget 18 Amp Brushless Motor ESC

- 4x 8g EMAX ES08A Sub Micro Servo

- Prop Adapter for 3.0mm shaft

- Landing gear assembly test.

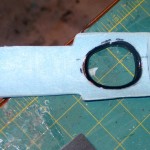

- Peanut butter jar cowling

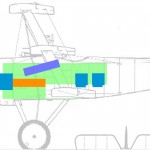

- The CG is much closer with the new component layout.

- Checking the CG with the new component layout.

- New component locations

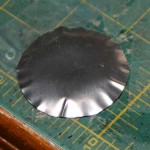

- A finished wheel

- Plastic sheeting glued onto the foam hub cap

- The raw materials for my wheels

- More flying wires running rearward to the fuselage.

- Installing the flying wires to brace the wings

- Using a bit of floss to figure out where the flying wires will pierce the wing.

- Decals for the tail

- Testing the position of the middle wing

- Testing the position of the middle wing

- Cabanes attached to top wing with screw eyes

- A bolt through the cabanes holds the lower wing on.

- An early look at the paint job

- Painting the fuselage blue

- Gluing the horizontal stabilizer on

- Torque tubes, aileron servos, lower ailerons installed

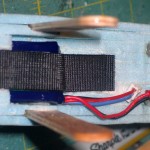

- ESC and wires jammed into their compartment

- Motor and motor mount installed

- Right servo pocket cut and servo in place

- Trying out the cockpit for size

- A potential pilot checks out the plane

- Test fitting the left aileron components

- The channel to hold the control rod tube.

- Aileron components

- Left aileron servo, poking thru the fuselage

- Left aileron servo, flush with the bottom of the wing

- Left aileron servo, flush with the bottom of the wing

- Might control horns make a nice fitting to bolt the struts to the wings?

- Velcro straps to hold the battery secure

- These magnets, on the blok, mate up with the battery hatch magnets.

- Rare earth magnets at the rear to help hold the battery cover in place.

- The cabanes extend through the bottom of the lower wing.

- Another test fit.

- Turtle deck and battery cover in progress

- The turtle deck, taped in place.

- The cabane struts in place.

- Cabane struts are mounted inside the fuselage skin.

- The cabanes are 1/2″ longer than the wing struts.

- Half of the mono-blok test-fit together

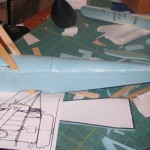

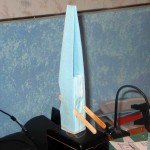

- A quick test assembly of the fuse, wings and empennage

- A quick test assembly of the fuse, wings and empennage

- All 8 blank mono-block pieces stacked in the fuselage

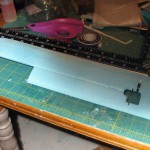

- Block layer templates printed out

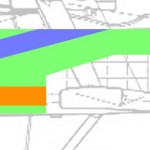

- Final component layout (Photoshop)

- Starting to lay out components in Photoshop

- Testing my sloppy wing jigs

- all three wings with camber and spars

- The battery cover is nearly complete

- I bend the camber into the wings with my fingers

- Finished wing from beneath, showing the rolled under-camber curve

- First test wing finished with LE spars, under-camber and ailerons

- Bamboo skewer spar epoxied to LE of wing

- Under-cambered wings with rib

- Balsa airfoil / ribs

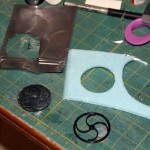

- All the parts cut out

- The ‘plans’ I’ll be working with

Pingback: [BLOCKED BY STBV] Yet another attempt at getting the Sopwith Triplane to fly. | Basement R/C

Pingback: [BLOCKED BY STBV] Winston flies (a little bit) | Basement R/C

The fliques are great! I have a few planes myself but they do not fly very much. I enjoy seeing other peoples sstuff in the air on video.

Chuck

Thanks, Chuck!

Pingback: [BLOCKED BY STBV] 1/12th scale Sopwith Triplane | Basement R/C