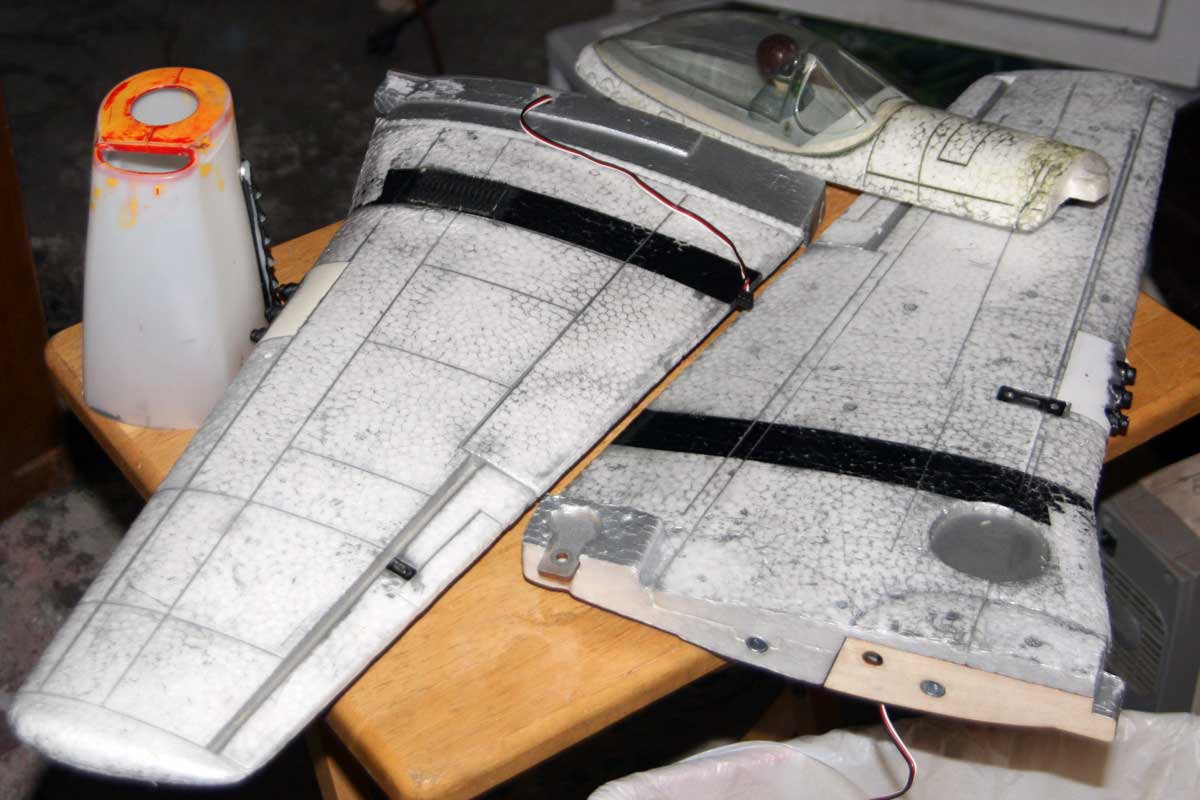

The time has come to overhaul my Tower Hobbies P-51.

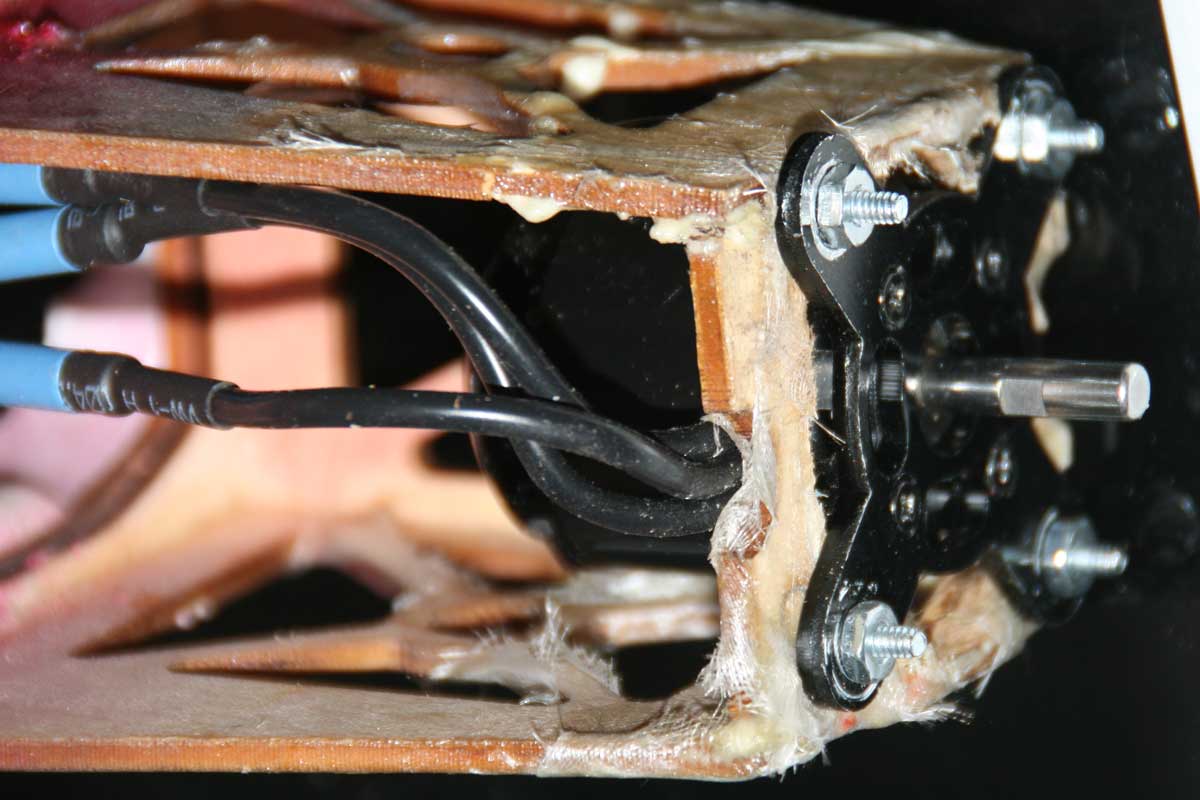

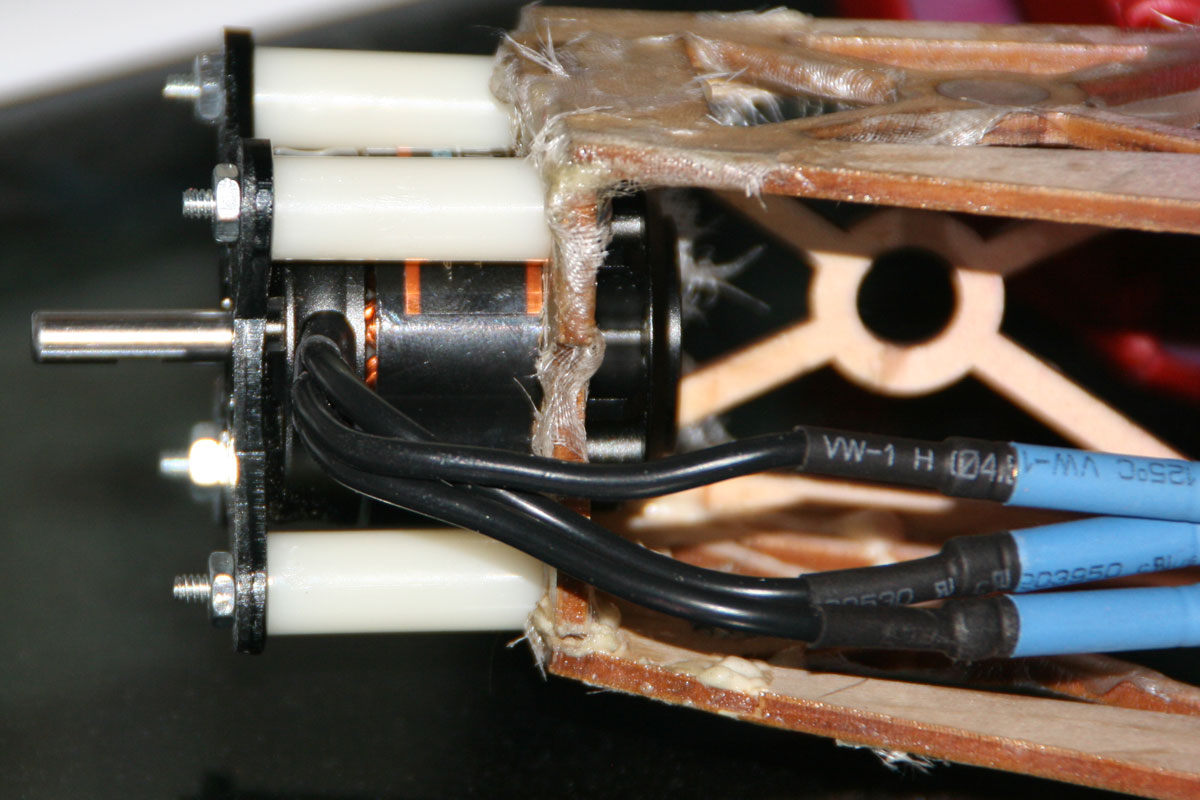

Per recommendations from Jesse at Headsup, I’ll be installing an Emax GT2815/05 1500kv motor and HURC 60 Amp ESC. They’ll be driving an APC 8x8E propeller with power from a 2700mAh 4-cell LiPo. Early calculations show that this setup should be somewhere between “really fast” and “extremely fast until the motor catches on fire.”

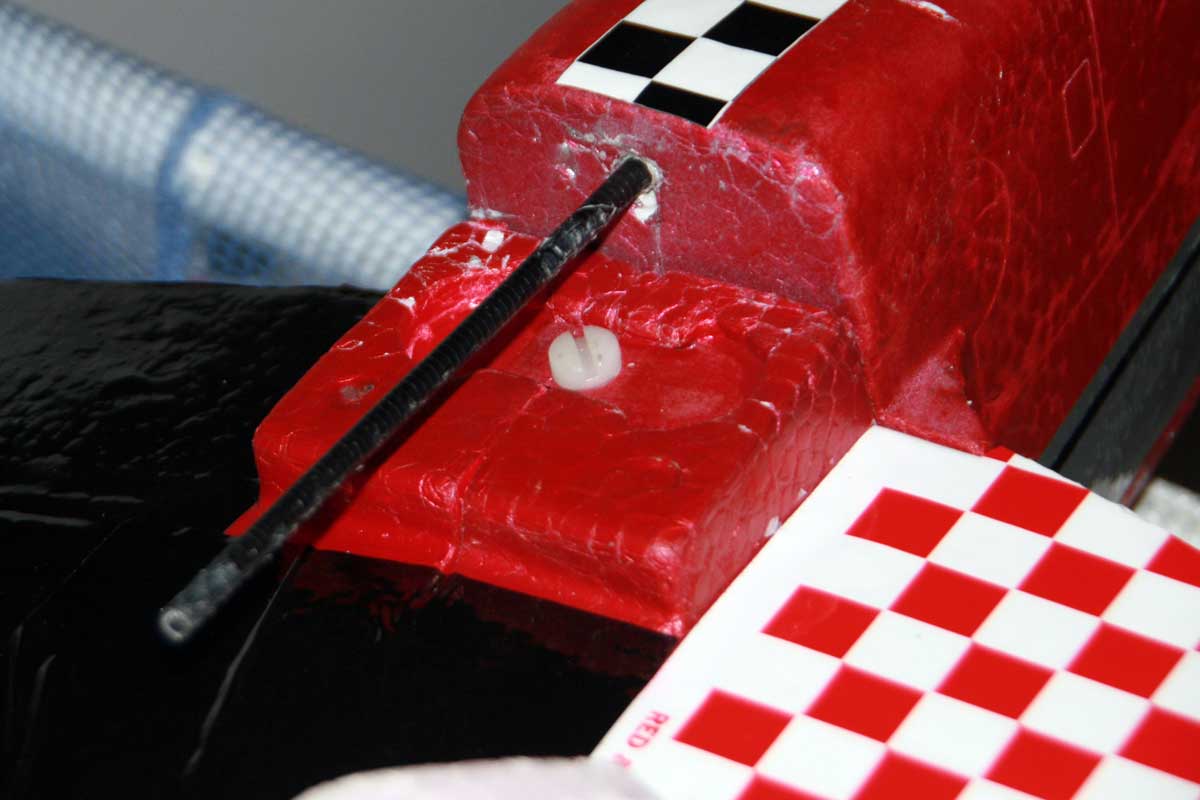

Red wings. I failed to get enough silver over that one stripe, and it shows through the red a bit, but the final graphics will cover that up.

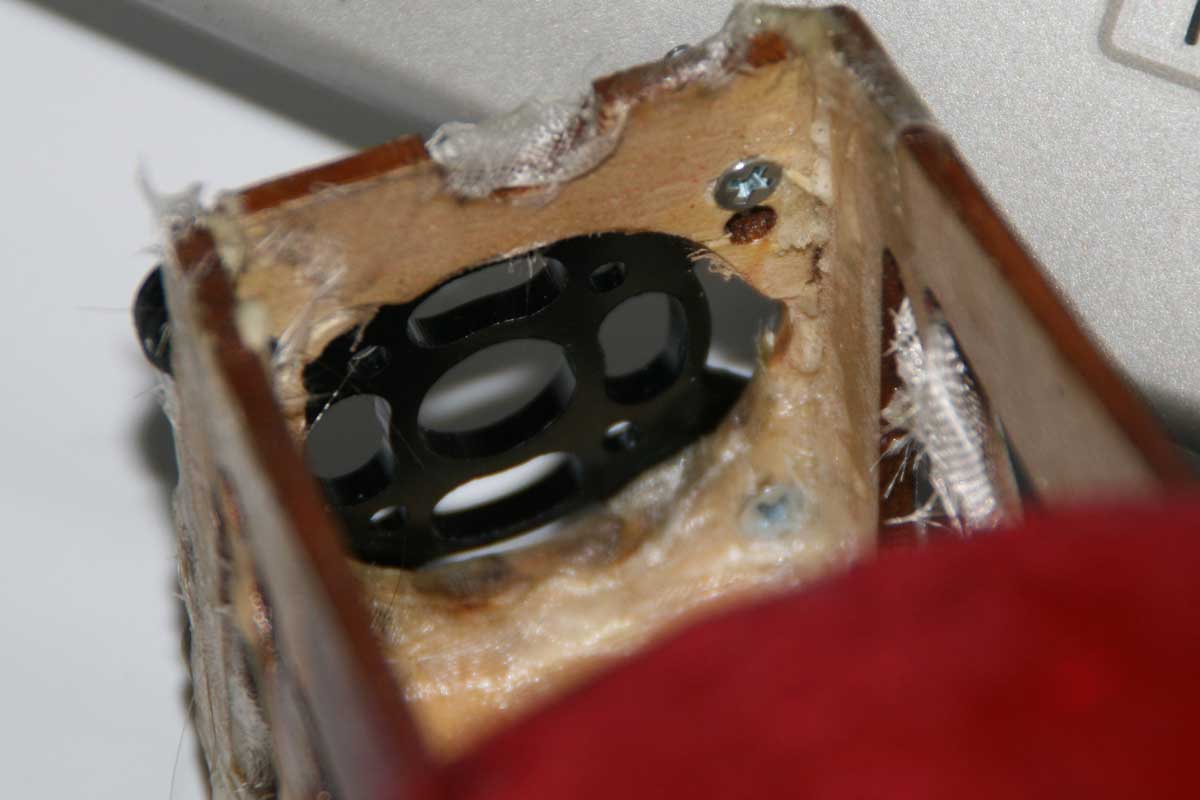

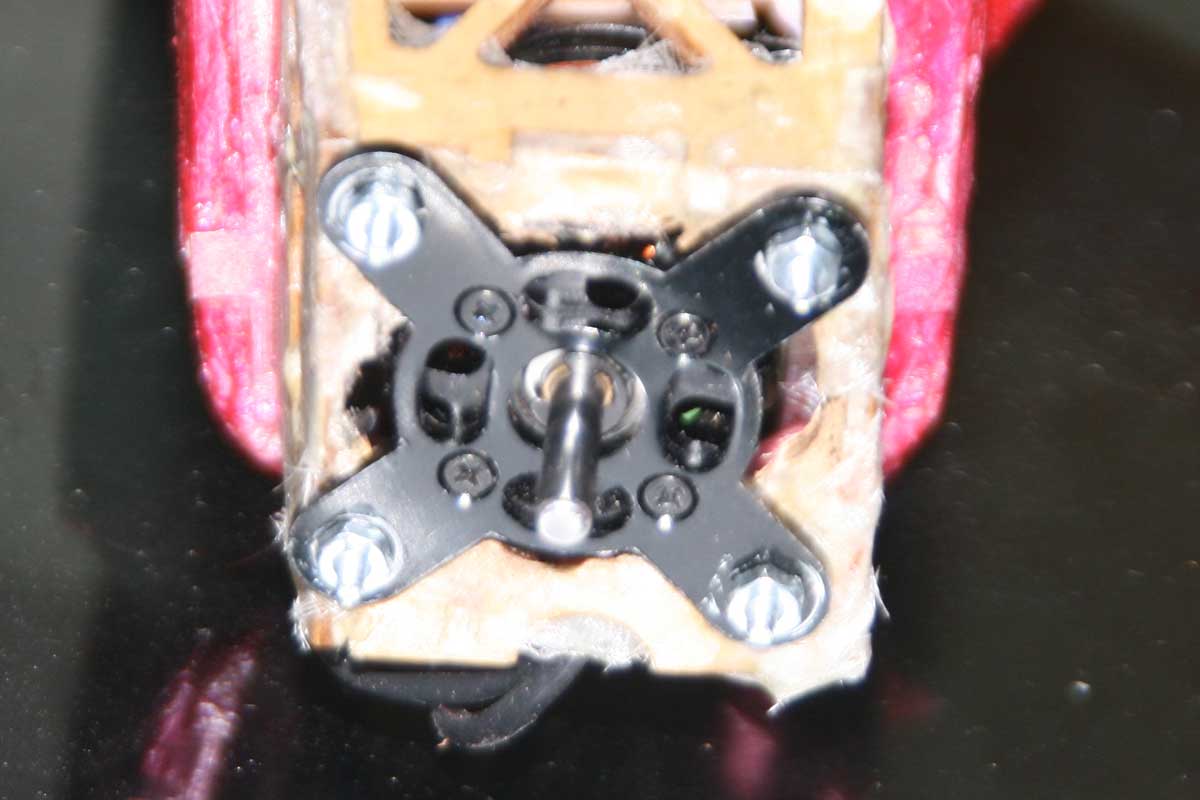

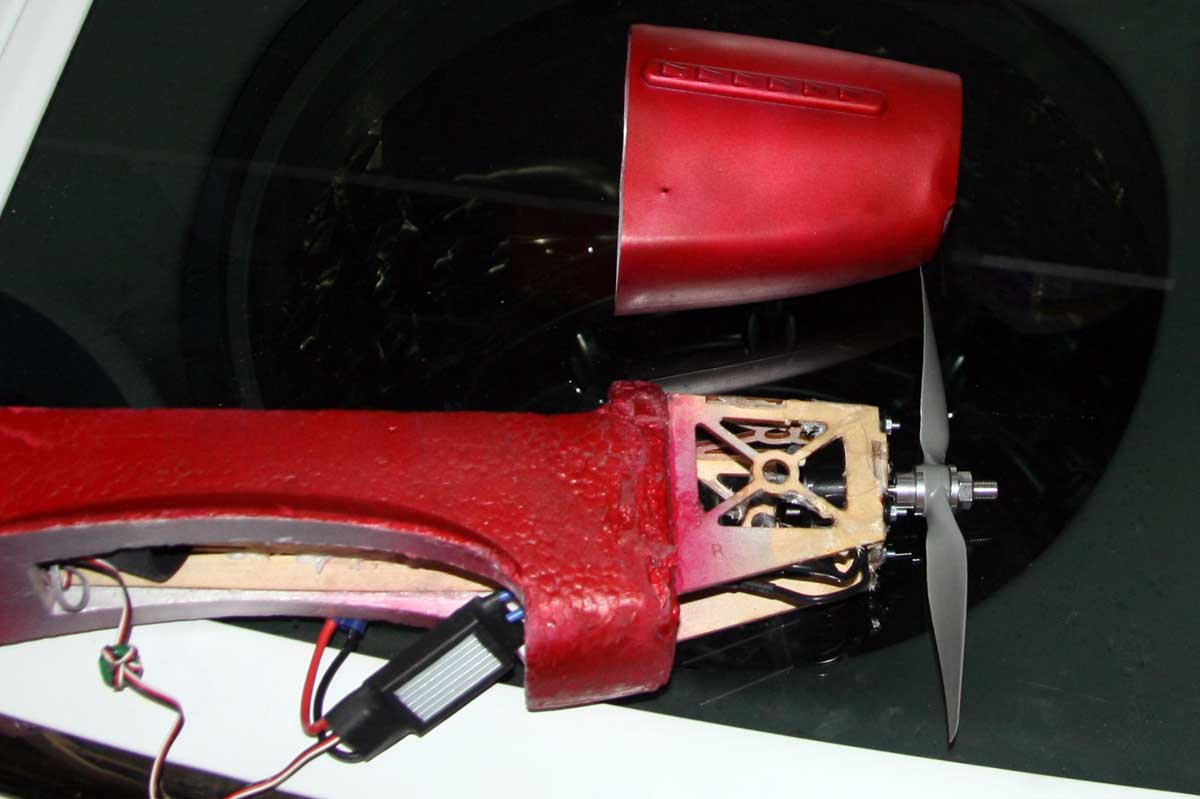

After cutting out the front of the stock wood mount, and reinforcing it with some (very sloppy) fiberglass work, I’ve bolted the new X mount in place.

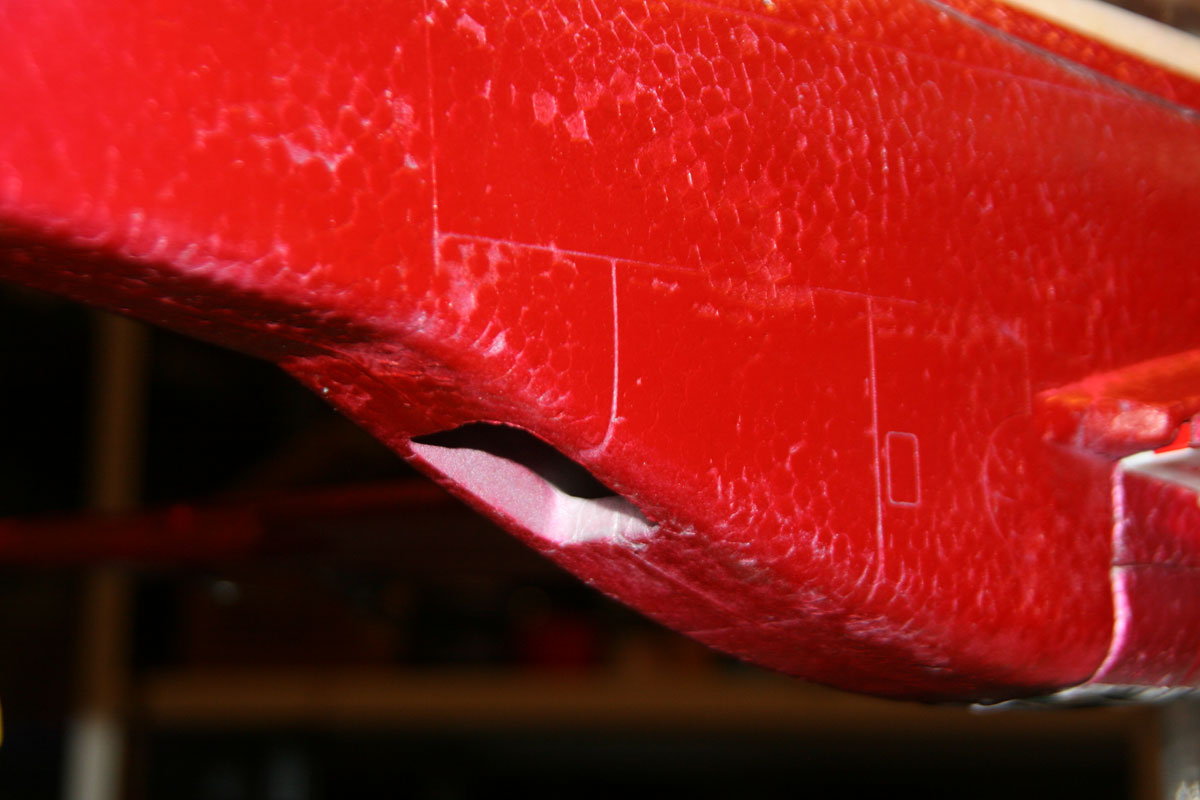

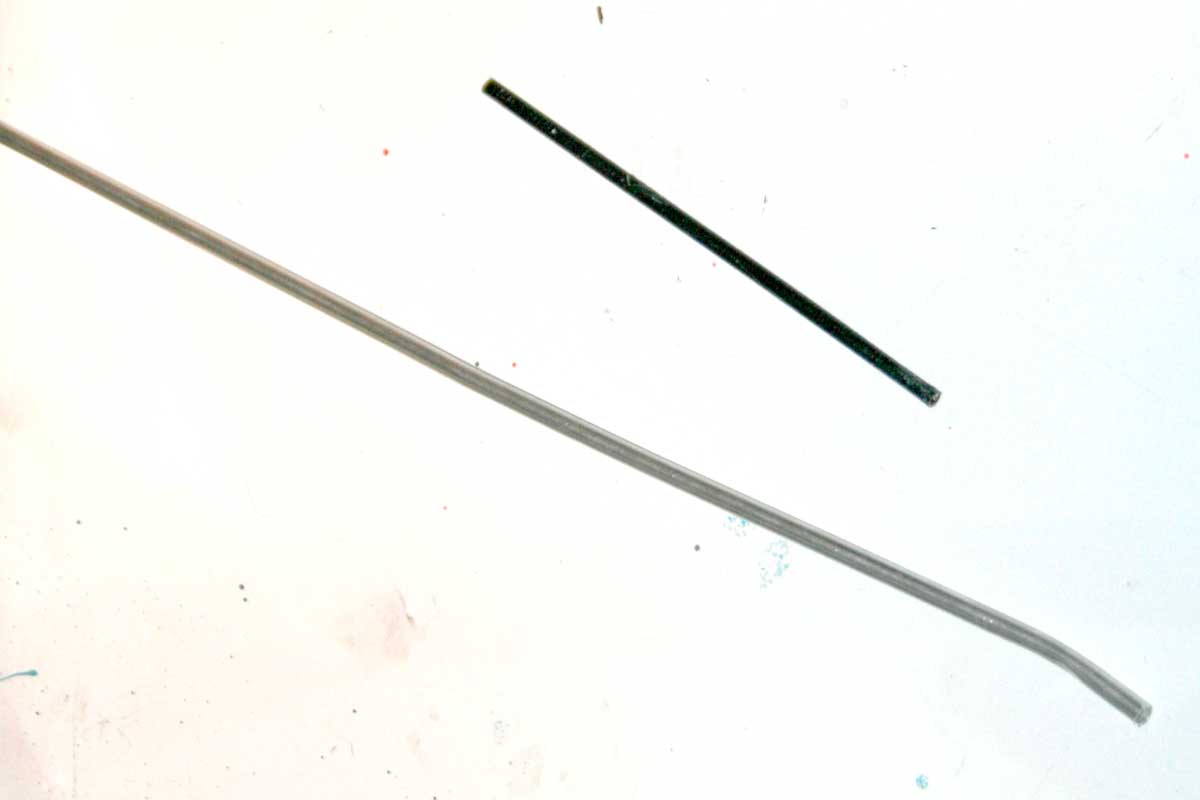

The air scoop is notoriously easy to detach during hand launching, so I’m trying something to hopefully help out. I’ve taken two short lengths of aluminum tubing and a short length of wing strut from an F-27C Stryker which just fits inside. I’ve Gorilla Glued the aluminum tubing inside the foam on the detachable air belly scoop, and also in the fixed, rear portion of the belly scoop. The wing strut fits inside them. Now, the scoop has to slide forward before it can detach.