I’ve been thinking lately that it might be fun to drop my baby Stryker from one of my bigger Strykers, in flight.

(Go here to see the first test flight.)

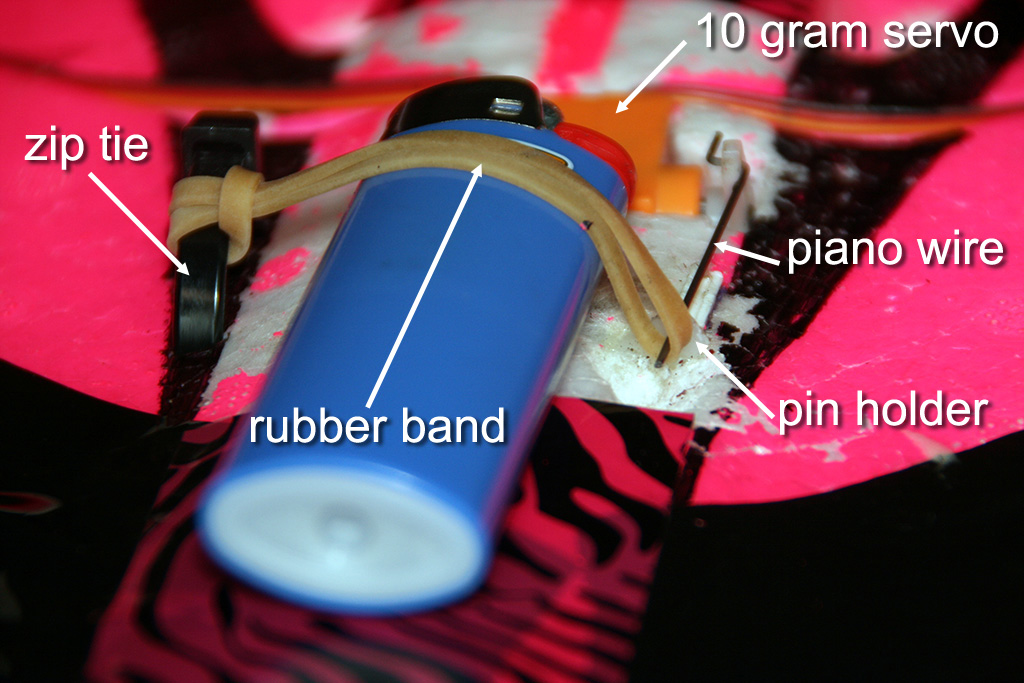

The rig uses a single 10 gram servo sunk into the bottom of the plane, with a short piece of piano wire acting as a pin. The pin fits through a hole in a pin holder fashioned from a spare servo arm, trimmed down and epoxied in place. A rubber band attaches to a loop of zip-tie, which passes completely through the wing and wraps around a length of bamboo skewer.

The other end of the rubber band fits over the pin, on the opposite side of the pin holder from the servo to keep the load off of the servo.

Shown here with a lighter rather than the baby Stryker, to allow a view of the working parts.

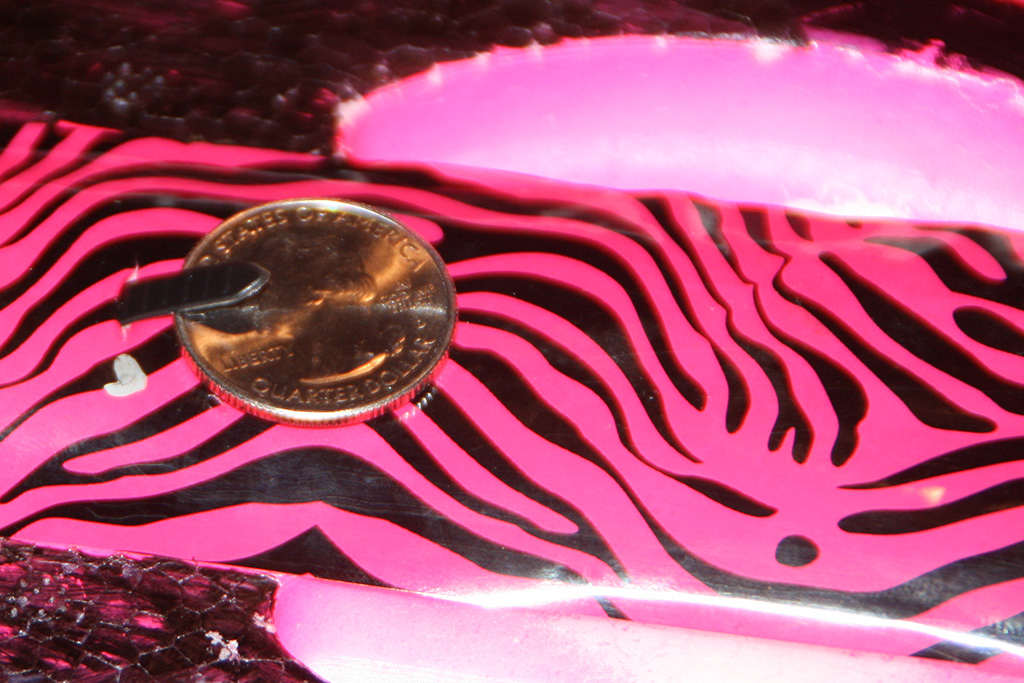

The rig is designed to drop the plane nose first. The rubber band holds the front on the plane snug, while the rear is held in place by a small ‘hook’ made from a length of flexible nylon zip-tie. I epoxied a short length of carbon fiber rod across the bottom rear of the baby Stryker’s fuselage. The hook slips between the rod and the fuse.

(The quarter’s just in there to make the ‘hook’ visible.)

I dug a hole in the big Stryker’s fuselage to accommodate the baby Stryker’s wheel and assure a firm, snug fit.

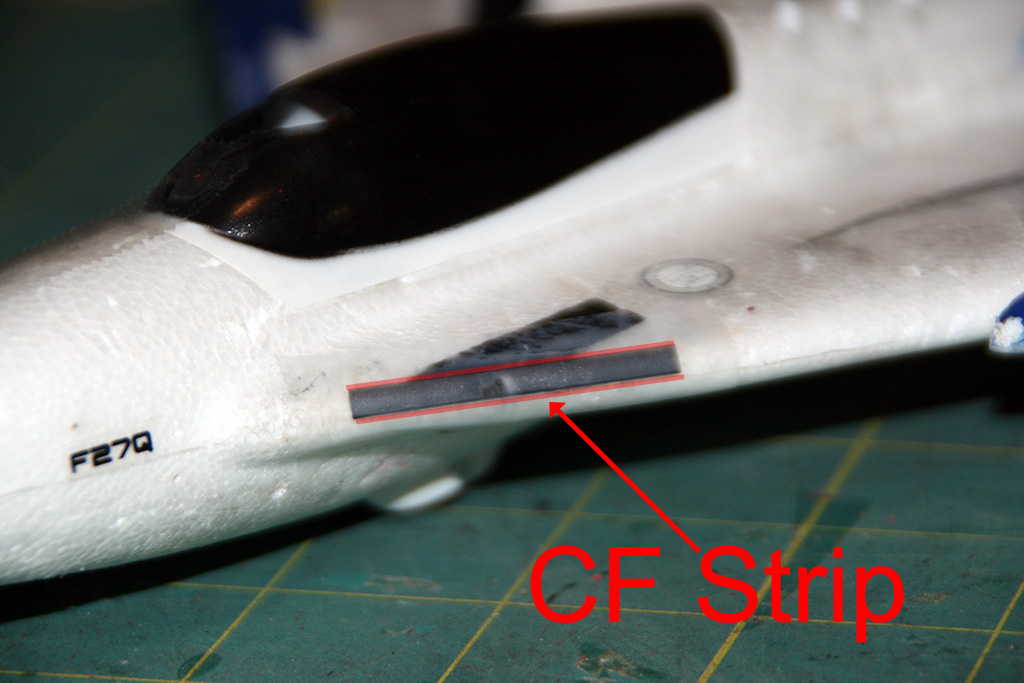

I epoxied a small carbon fiber strip to the top of the leading edge of each wing to keep the rubber band from digging into the foam.

Here’s what it looks like, mounted to the bottom and ready to drop.

Here’s a stationary drop-test of the rig: